一、由人員更換氣體增壓泵的密封。

1、 The seal of gas Booster pump shall be replaced by personnel.

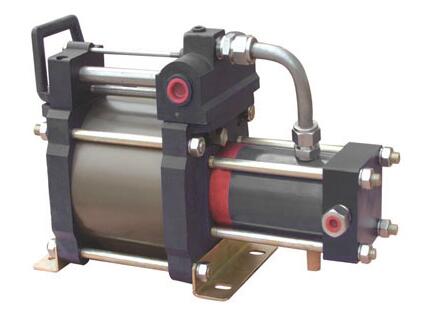

氣液增壓泵這種結構簡(jiǎn)單緊湊的產(chǎn)品,組裝起來(lái)并不困難,但是需要相關(guān)的培訓,否則很容易因為組裝原因導致產(chǎn)品無(wú)法正常運行。這類(lèi)產(chǎn)品主要由缸筒、儲油桶、油缸、活塞、密封件等組成。其中有幾十種不同規格尺寸的密封圈,分別用在活塞上、中蓋上、前蓋上等部位。安裝時(shí)注意細節,否則容易損壞密封件。建議由人員更換,或聯(lián)系氣動(dòng)增壓泵廠(chǎng)家更換。

The gas-liquid Booster pump, a simple and compact product, is not difficult to assemble, but needs relevant training, otherwise it is easy to cause the product to fail to operate normally due to assembly reasons. This type of product mainly consists of cylinder barrels, oil storage barrels, oil cylinders, pistons, seals, etc. There are dozens of different specifications and sizes of sealing rings used on pistons, middle covers, front covers, and other parts. Pay attention to details during installation, otherwise the seal may be damaged. It is recommended to replace it by personnel or contact the manufacturer of pneumatic Booster pump for replacement.

二、氣液增壓泵更換密封前的注意事項

2、 Precautions before seal replacement of gas-liquid Booster pump

1.檢查前軸。

1. Check the front axle.

安裝油封前,檢查前軸表面是否太粗糙,是否有嚴重的磕碰。氣動(dòng)增壓泵長(cháng)期運行產(chǎn)生的軸向長(cháng)拉上。如里軸表面過(guò)于干燥、粗糙、不光滑,會(huì )使油封揭壞,影響密封性能。如果軸面拆裝不當,會(huì )造成嚴重拉傷,油封與軸面貼合有縫,導致漏油。在這種情況下,建議更換新軸,因為軸表面必須有很高的光潔度。

Before installing the oil seal, check if the surface of the front axle is too rough and if there are serious bumps. Long axial pull up caused by long-term operation of pneumatic Booster pump. If the surface of the inner shaft is too dry, rough, or unsmooth, it will cause the oil seal to peel off and affect the sealing performance. If the shaft surface is not disassembled properly, it can cause serious strain, and there is a gap between the oil seal and the shaft surface, leading to oil leakage. In this case, it is recommended to replace the shaft with a new one, as the surface of the shaft must have a high smoothness.

2.檢查軸頭。

2. Check the shaft head.

對于只有金屬手刺或邊緣的簡(jiǎn)單軸頭,可以用鏗力打磨平整,防止安裝油封時(shí)劃傷油封唇目,然后檢查油封質(zhì)量是否有破損、裂紋或油污。如果發(fā)現這些不良現象,油封不能使用,必須更換新的。

For simple shaft heads with only metal hand pricks or edges, they can be polished flat with steel force to prevent scratching the oil seal lip when installing the oil seal. Then, check the quality of the oil seal for damage, cracks, or oil stains. If these defects are found, the oil seal cannot be used and must be replaced with a new one.